Software Development

- Software Development Design.

- Embedded Software Development for Body Control Module, Engine Management System, Instrument Cluster Node, . . .

- Embedded Software Development in Different Layers (Application - Communication – Diagnostic) based on MISRA Rules

- Bootloader Development for Automotive Microcontrollers

- Software Quality Checking Tools (QAC, TESSY, . . .)

- Software & Hardware Automatic Test (HIL)

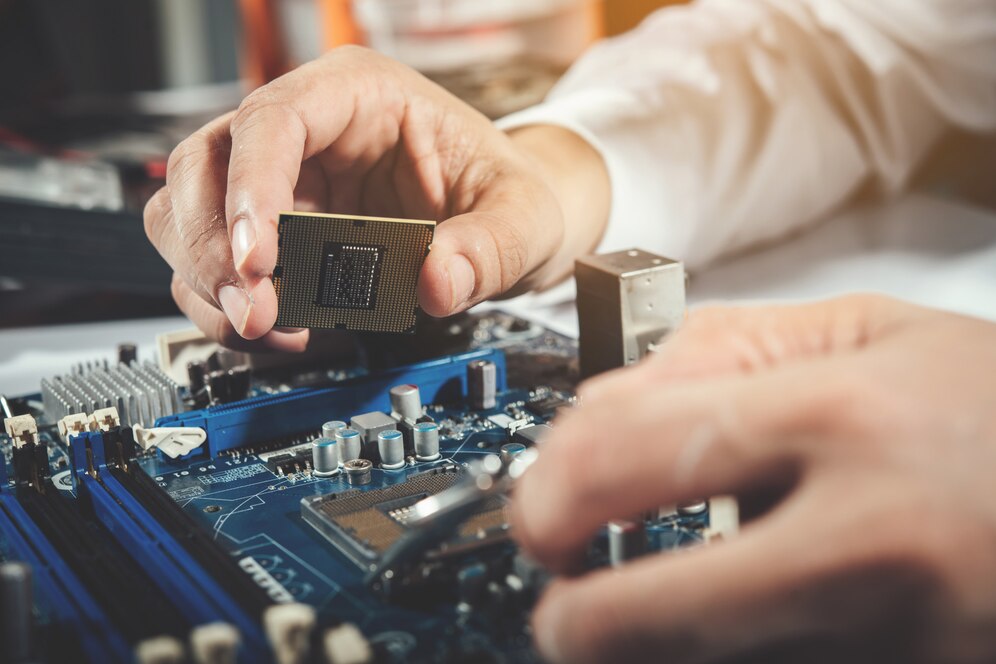

Hardware Development Design

Design of electronic units based on Customer Requirements:

- Networks Compatibility (HS CAN – LS CAN – LIN)

- Working Conditions

- Packaging

- Vehicle Topology

- Customer Requirements Satisfaction.

Designing the Structure of Automotive Multiplex Networks:

- Fuse & Relay Box Structure

- Functional Diagram

Hardware Simulator Design for Laboroatory Tests.

Mechanical Parts Development

- Employing Sophisticated 3D CAD Modeling Softwares such as CATIA, SOLIDWORKS, AUTODESK INVENTOR or AUTOCAD to Create theDraft Design of Products.

- Develop Prototypes and Conducting a Variety of Tests on Different Types of Mechanical Parts in Close Cooperation with Manufacturing Teams to Ensure if Design Criteria and Specifications are Met.

- Documenting the Design Process, Iterations, and Test Analysis.

- Design Optimisation and Materials Selection Considering: Best Manufacturing Processes, Lifetime Requirements, Regulatory and Safety Standards, Recyclability and End-of-Life Disposal.

- Design for Manufacturing (DFM) Including Doing All the Tasks Associated with Making a Fully-Functional Prototype till Mass Production Considering Supply Chain Selection, Design Optimization and Packaging Criterias.

- Detailed Analysis Services Including: Functional Analysis, Failure Analysis, Finite Element Analysis (FEA); Linear and Non-Linear Materials, Static and Dynamic Analysis, Thermal Analysis, Computational Fluid Dynamics (CFD), and Large Displacement Models.

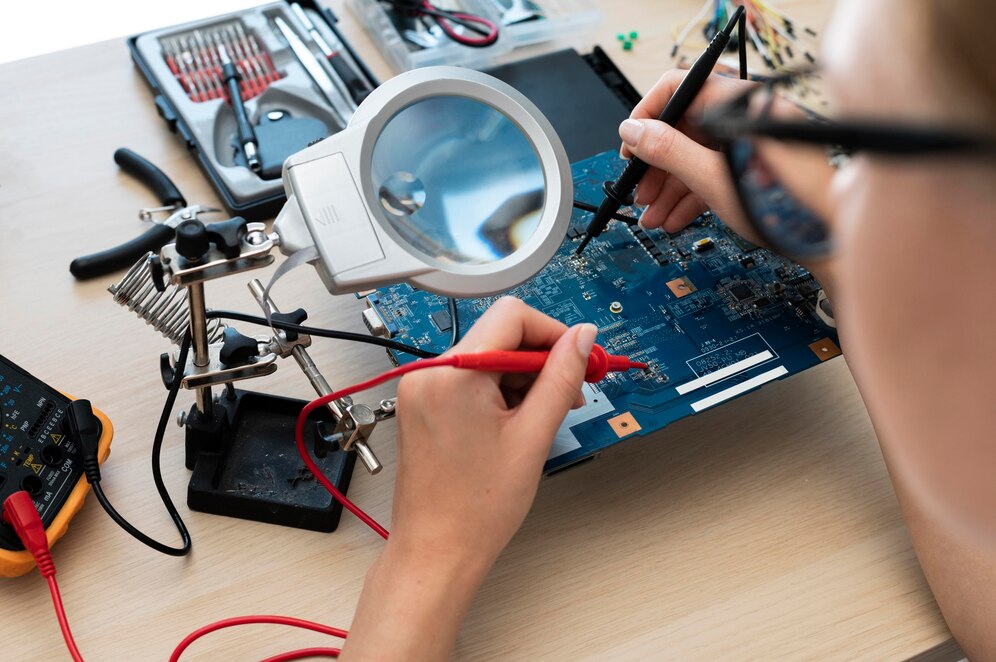

Validation

- Software Test Bench and Simulators Design for Software Development and Validation.

- Performing Static and Dynamic Software and Hardware Validation Tests.

- Matrix Requirement Preparation based on Product Design and Development Documents and Standards.

- Hardware Validation Tests Including: Environmental / High-Temperature / Low - Temperature / Humidity / Sealing and Corrosion / Electrical and Electronic / CAN-LIN Physical Layers / ESD / Short Circuits / Overload / Open load / Durability / Performance / Unitary / Integration / Vehicle Tests.

- Advanced Equipment for Data Collection and Analysis of Vehicle Data Transmission Networks such as CAN Analyzer , LIN Aanalyzer, Network Data Loggers.

Vehicle Electrical Structure Design

- Topology Design of Electronic Control Units.

- Functional Drawings.

- Fuse & Relay Box Structure.

Investment & Engineering Consultancy

Product Proposal

Offering Suitable Product for Investment Based on Market Needs and Trends of Technology.

Market Analysis

Conducting Market Research and Analysis to Identify Opportunities, Assess Competition, and Understanding Consumer Preferences.

Resource Sourcing

Assisting in the Procurement of Necessary Resources Including Raw Materials, Technology and Labor, Considering Important Factors such as Cost, Availability and Quality.

Design Engineering

Providing Engineering Design Services to Conceptualize and Develop the Product, Ensuring Functionality, Efficiency and Compliance with Standards and Regulations.

Manufacturing Planning

Devising Production Strategies and Plans, Optimizing Processes for Cost-Effectiveness, Scalability, and Quality Assurance.

Continuous Research and Development

Supporting Research and Development Activities to Improve Existing Products and Introduce New Products Employing Advanced Technologies and Innovative Methods.

Production Implementation

Overseeing the Implementation of Manufacturing Processes, Including Setting Up Facilities, Training of Personnel Ensuring Smooth Operations.

After-Sales Support

Offering Post-Production Maintenance, Repair, and Technical Assistance Services to Ensure the Product's Continued Performance and Customer Satisfaction.

Production Process Optimization

Consulting and Providing Solutions to Improve Efficiency and Productivity in Manufacturing Processes, including the adoption of new technologies and Increaseing Automation.

Customer Feedback

Gathering and Aanalyzing Customer Feedback about Products and Services and Making Necessary Changes and Improvements to Increase Customer Satisfaction.

Training and Technical Education

Providing Training Courses for Employees and Customers about Product Usage, Maintenance and Repair to Increase Technical Knowledge and Enhance Product Utilization.

Waste Management and Environmental Remediation

Providing Management Solutions to Reduce Waste and Environmental Impacts of Products and Production Processes.

Production Line Design and Analysis

- Planning, Design and Manufacturing of Digitalized Automation Solutions for Efficient Assembly Line Using for Mass Production.

- Simulation and Optimization of Production Systems and Processes Including Material Flow Analysis and Selection of Appropriate Level of Automation.

- Virtual Simulation of Production Process Employing 3D Application.